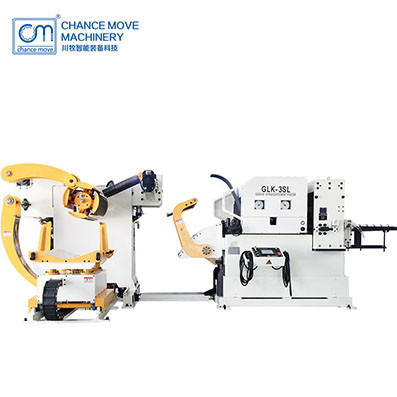

中板专用三机一体式伺服开卷整平送料机

- Model

- GLK3

Review

Description

产品描述

GLK3 中板专用三机一体式伺服开卷整平送料机

产品特点

1.创新的机械结构,使全机所需空间缩至最小。

2.采用人机界面,操作简单,方便送料。

3.采用进口伺服系统,确保高精度送料。

4.送料滚轮及整平滚轮经特殊热处理,硬度高(HRC62°)。

5.多样的几种选择,更适合冲床大小及作业的需求。若有特殊规格需求,本公司亦可承制。

1.台车

承载面为V字式结构,表面进行喷漆防锈处理

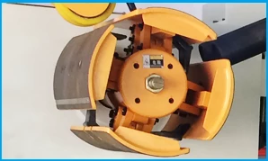

2.料架主轴

扩张方式采用液压拉杆式,主轴传动双排大节距链条传动

3.压料臂

采用气缸驱动

4.入料口

摆臂控制采用触摸屏控制,气缸驱动,用于材料料头进入整平机的导正,使材料平顺地进入整平装置

5.控制面板

6.整平部分

矫正量调整采用偏心涡轮蜗杆调节了,对材料进行整平工作,并按照要求做定尺送料的机构

7.手轮

刻度盘显示,偏心轴端带刻度盘做参考

8.出料口托料架

托料架端面安装伸缩把手,手动拉出即可

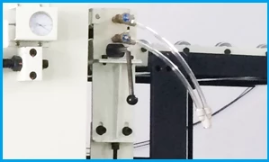

9.涂油装置

用于材料表面的涂油工作

规格参数

型号 | GLK3-400 | GLK3-600 | GLK3-800 | GLK3-1000 |

适用材料宽度(mm) | 50-400 | 50-600 | 50-800 | 50-1000 |

适用材料厚度(mm) | 0.3-4.5 | 0.3-4.5 | 0.3-4.5 | 0.3-4.5 |

最大卷重(kg) | 5000 | 5000 | 7000 | 7000 |

卷料内径(mm) |

508 |

508 |

508 | 508 |

卷料外径(mm) | 1400 | 1400 | 1400 | 1400 |

最大送料长度(mm) | ~500※ | ~500※ | ~500※ | ~500※ |

最大送料速度(m/min) | 16-24 | 16-24 | 16-24 | 16-24 |

工作滚轮 | 上4/下3 | 上4/下3 | 上4/下3 | 上4/下3 |

送料滚轮 | 1 | 1 | 1 | 1 |

伺服电机 (kw) |

AC4.4 |

AC74.4 |

AC5.5 | AC7.5 |

料架扩张方式 |

油压 |

油压 |

油压 | 油压 |

料架电机(kg) |

2.2 |

2.2 |

2.2 3.7 | 3.7 |

使用电源电压(V) | 200/380 | 200/380 | 200/380 | 200/380 |

使用空气压(Mpa) | 0.49 | 0.49 | 0.49 | 0.49 |

矫正能力

型号 | GLK3-400 | GLK3-600 | GLK3-800 | GLK3-1000 | |

板厚 (mm) | 0.3~0.8 | 400 | 600 | 800 | 1000 |

1.0 | 400 | 600 | 800 | 750 | |

1.2 | 400 | 600 | 700 | 600 | |

1.6 | 400 |

590 |

480 |

430 |

|

1.8 | 400 |

500 |

420 |

380 |

|

2.0 | 400 |

430 |

370 |

330 |

|

2.3 | 400 |

360 |

320 |

290 |

|

2.8 | 370 | 290 | 250 | 230 | |

3.2 | 300 | 250 | 220 | 200 | |

4.5 | 160 | 160 | 150 | 110 | |

上表中的降服点应力为245N/mm²

案例

GLK3大连爱丽思

GLK3-1600成都长瑞