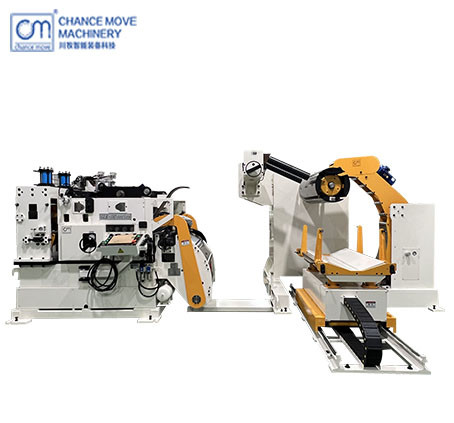

可掀开式高涨力板材专用三机一体式开卷整平送料机

- Model

- GLK4-H

Review

Description

产品描述

GLK4-H 可掀开式高涨力板材专用三机一体式开卷整平送料机

产品特点

1.创新的机械结构,使全机所需空间缩至最小。

2.操作面板采用彩色液晶显示器,大尺寸的触摸屏,高清晰的操作画面,配合操作安全系统,即便是初次使用者也能安心操作。

3.健全的操作系统人性化设计,将准备工作缩短,先进的自动诊断系统,协助操作者快捷掌控本机的卓越性能。

4.采用进口伺服系统,确保高精度送料。

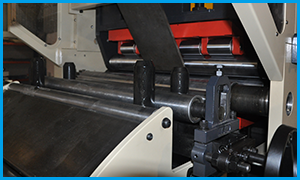

5.送料滚轮及整平滚轮经特殊热处理,硬度高(HRC62°)耐磨,寿命长。

6.特别为强力厚板而设计的上下整平背压滚轮组,可达到保证的应力消除效果。

7.将安全系数增强一倍的设计理念,令设备安全使用寿命更加延长。

8.多样的几种选择,更适合冲床大小及作业的需求。若有特殊规格需求,本公司亦可承制。

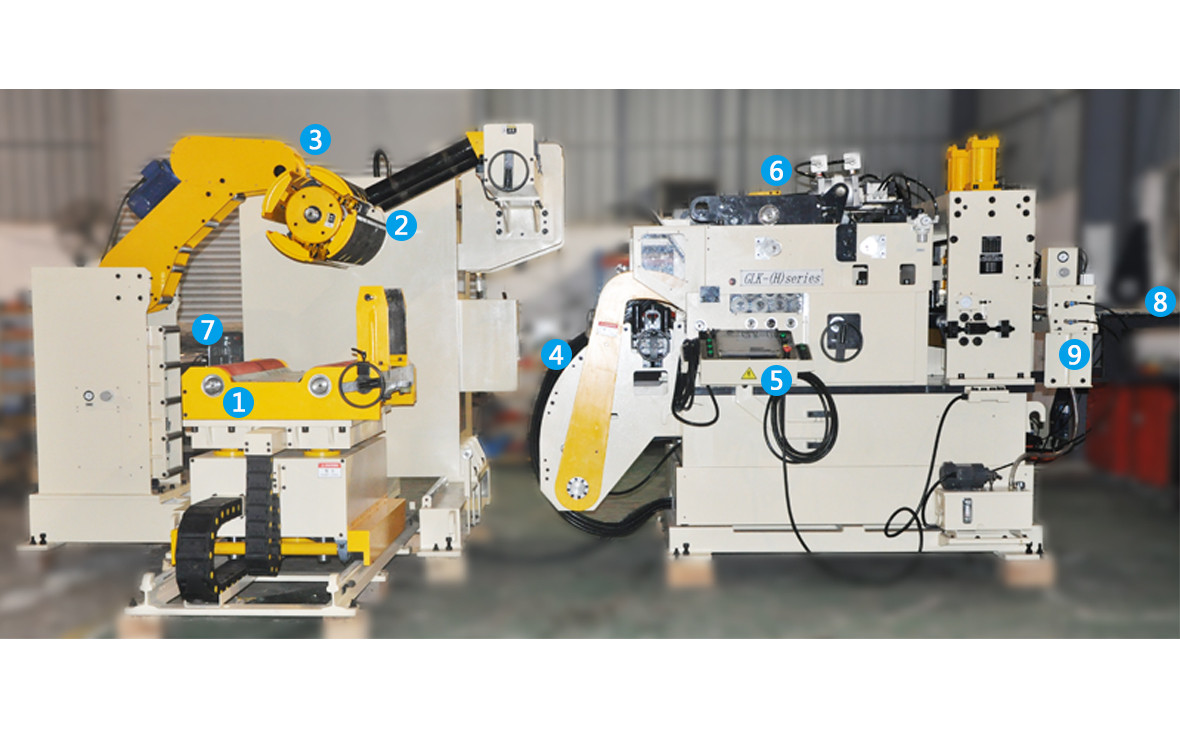

1.台车

把材料安全平稳地移动到开卷机主轴扩缩结构上,在开卷时用来托起材料,方便料带能够顺利地进入整平机,台车装备防止料卷倾倒机构,用于移动较窄料卷。

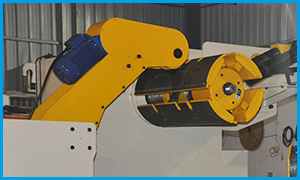

2.料架主轴

将料卷内径固定在扩缩部位,并且根据要求把材料按照要求做间隙性转动的放料的平台

3.压料臂

运行中压紧材料,防止料卷散料,自动运行过程中,压料轮会随着材料外径的改变自动调整速度,使压料轮与料卷的线速度完全匹配,杜绝料卷的散开。

4.入料口

用于材料料头进入整平机的导正,使材料平顺地进入整平机构

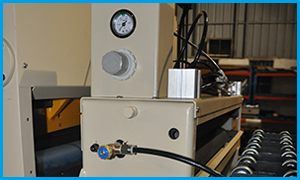

5.控制面板

主要电气采用日本进口安川伺服马达及整套三菱控制系统,以及进口触摸屏、PLC及变频器。操作面板控制按钮采用日本富士等知名产品。

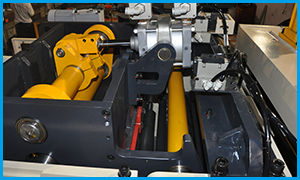

6.整平部分

对材料进行整平工作,并按照要求做定尺送料的机构,上整平轮组可掀开结构,掀开时可进行滚轮表面清洗工作。

7.液压装置

8.出料口托料架

用于定尺送料后与模具之间的平顺传送,托料架上安装优质进口耐磨福来轮

9.涂油装置

用于材料表面的涂油工作,并且涂油量以及涂油间隔实现电子控制以及可调式

规格参数

型号 | GLK04-600H | GLK04-800H | GLK04-1000H | GLK04-1300H |

适用材料宽度(mm) | 70-600 | 70-800 | 70-800 | 70-1300 |

适用材料厚度(mm) | 0.6-6.0 | 0.6-6.0 | 0.6-6.0 | 0.6-6.0 |

最大料重(kg) | 5000 | 5000/7000 | 7000 | 7000 |

卷料内径(mm) |

508 |

508 |

508 | 508 |

最大卷料外径 (mm) | 1400 | 1400 | 1400 | 1400 |

最大送料长度(mm) | ~500※ | ~500※ | ~500※ | ~500※ |

送料速度(m/min) | 16-24 | 16-24 | 16-24 | 16-24 |

矫正滚轮 | 上5/下4 | 上5/下4 | 上5/下4 | 上5/下4 |

送料滚轮 | 1组 | 1组 | 1组 | 1组 |

伺服马达 (kw) |

AC7.5 |

AC11 |

AC11 | AC15 |

料架扩张方式 |

油压 |

油压 |

油压 | 油压 |

使用电压(V) |

2.2 |

2.2 3.7 |

3.7 | 3.7 |

料架马达(kw) | 200/220 | 200/220 | 200/220 | 200/220 |

使用空气压 (Mpa) | 0.49 | 0.49 | 0.49 | 0.49 |

矫正能力

型号 | GLK04-600H | GLK04-800H | GLK04-1000H | GLK04-1300H | |

板厚(mm) | 0.8~2.3 | 600 | 800 | 1000 | 1000 |

2.5 | 933 | 933 | |||

2.8 | 920 | 920 | |||

3.2 | 714 | 714 | 714 | ||

4.0 | 457 |

457 |

457 |

457 |

|

4.5 | 361 |

361 |

361 |

361 |

|

5.0 | 293 |

293 |

293 |

293 |

|

4.56.0 | 203 |

203 |

203 |

203 |

|

上表中的降服点应力为245N/mm²

矫正能力

型号 | GLK04-600H | GLK04-800H | GLK04-1000H | GLK04-1300H | |

板厚(mm) | 2.5 | 255 | 252 | 250 | 146 |

2.8 | 205 | 203 | 202 | 199 | |

3.2 | 177 | 175 | 174 | 171 | |

4.0 | 138 | 136 |

135 |

133 |

|

4.5 | 120 | 119 |

118 |

116 |

|

5.0 | 106 | 105 |

104 |

103 |

|

6.0 | 81 | 81 |

81 |

81 |

|

案例

GLK4-600H成都长瑞

GLK4-800H-J重庆凯安

GLK4-1000H长春CAPP

GLK4-1300H-J武汉新途